A peek inside the cavern: Building the Willow Rock Energy Storage Center—and powering California’s energy future

As the global energy landscape shifts toward energy security and independence, the need for resilient, flexible, and reliable power systems has never been more urgent. Long-duration energy storage (LDES) technologies are emerging as a cornerstone requirement in future grid planning, offering the ability to store energy for hours, days, or even weeks.

LDES enables deep integration of intermittent renewables like solar and wind, helping to balance supply and demand across longer timescales and weather cycles. Incorporating LDES into grid infrastructure is not just a technical upgrade—it’s a strategic imperative.

California, a longtime leader in energy innovation, is already paving the way. This is why Hydrostor is building its first Advance Compressed Air Energy Storage (A-CAES) plant in Kern County, California.

Continue reading to learn how the 500 MW Willow Rock Energy Storage Center and the future of California’s grid is being built, one underground cavern at a time.

Not your grandma’s energy storage

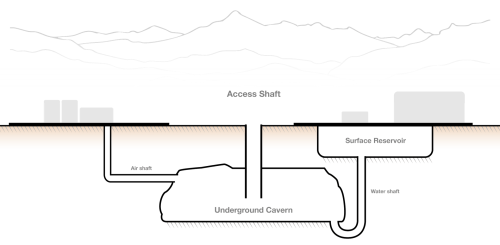

To understand how to build a project like Willow Rock, you first need to understand how A-CAES technology works. The WRESC operates by running excess power from the grid through turbines and then compressing air, which is then pumped into a large, water-filled cavern 2,000 feet underground. The heat removed from the air in the compression process is stored for later, and the cavern below-ground fills with compressed air while a surface reservoir holds the water above.

When the grid needs power—like during peak winter demand or an extreme weather event—the process is reversed, and the stored energy gets dispatched back to the grid. While it might sound like science-fiction, A-CAES simply utilizes long-established principles of thermodynamics, along with components and know-how from the oil & gas and mining industries, and readily available rock, water, and air to store and deliver energy at-scale and on-demand.

Once built, Willow Rock will provide 500 MW of dispatchable electricity for 8-plus hours to Kern County and California’s grid. But Willow Rock’s benefits extend far beyond its functionality.

From breaking ground to commissioning, building Willow Rock will take a $1.5 billion investment, five years of construction, and more than 6,500 workers, along with more than $500 million in community benefits. Once operational, the WRESC will support 40 highly skilled, full-time jobs over the plant’s lifespan of more than 50 years.

Digging deep to supply multi-generational energy storage

Constructing LDES infrastructure as vast and enduring as Willow Rock is a massive undertaking and takes time, resources, and care deployed over a multi-phased construction process. Building will involve six distinct and equally important stages:

- Preconstruction planning

- Subsurface excavation

- Topside construction

- Transmission line interconnection

- Testing and adjustments

- Startup and operations

Let’s dig into each one and explore what it will achieve and why it matters.

1. Preconstruction planning (completed)

A project of this magnitude requires meticulous planning and preliminary due diligence before the site can become shovel-ready. Phase 1 involves months of preconstruction assessment, ensuring that Willow Rock’s many benefits do not come at the expense of the local community, or environment. Before any ground is broken at Willow Rock, Hydrostor evaluates the project’s impact in a number of ways.

Hydrostor also works closely with the local community and state and federal government agencies to get permits prior to construction.

2. Subsurface excavation

Excavation is the second and longest project phase of Willow Rock’s construction. To build the underground cavern, the shafts that carry water, air and equipment between the surface and the cavern, and the above-ground reservoir at the core of Willow Rock’s A-CAES technology, it takes about 3 years, with an average of almost 100 workers on-site every single day.

First, and closest to the surface, the water reservoir is excavated, which takes roughly 14 months, creating a 600-acre-foot reservoir. This holds about as much water as the San Diego wastewater processing plant treats in a single day. And once filled, the reservoir will never need another drop of water—it will even generate additional water through condensation from operation.

The construction team next excavates the access shaft, digging through bedrock at a pace of approximately 5 to 8 feet per day, reaching the 2,000 foot mark after 250 to 400 days of construction. The access shaft allows for the subsequent excavation of the air and water shafts and rock cavern, enabling the crew to send the necessary excavation equipment underground piece by piece.

The water shaft contributes to the A-CAES process by carrying water between the cavern and topside reservoir. Lined and cemented into place during construction, this shaft maintains a water seal by extending into a sump below the cavern floor. In parallel, the air shaft conveys compressed air between the cavern and surface reservoir.

Similar to the water shaft, the air shaft is also lined and cemented into place during construction for maximum structural integrity. Finally, the rock storage cavern is constructed up to 2,500 feet below ground using a room-and-pillar layout, which is a grid-like mining structure that ensures geological and structural stability.

Thanks to these foundational infrastructure components, Willow Rock can store, move, and deploy excess energy between the grid, shafts, cavern, surface reservoir, and thermal storage tanks through a transformative flow of air, heat, and water. The end result is energy storage composed of synergistic parts functioning like an integrated organ system.

3. Topside construction

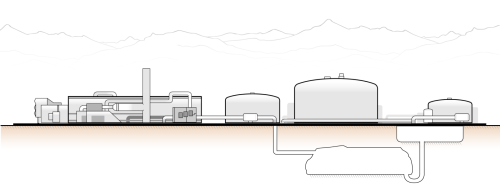

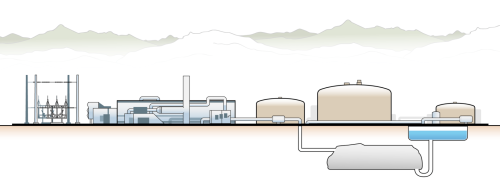

Once the deep bedrock excavation is well underway, surface construction begins in parallel. Over the course of 30 months, on average more than 450 onsite workers build and install the other essential components of the A-CAES technology, including turbines and thermal storage tanks.

Some of the most important structures installed during this phase are the four 125 MW (net) generating trains that enable Willow Rock to store, move, and dispatch excess energy to the grid on demand. Each train has multiple parts that work synchronously. For example, the electric motor-driven air compressor drive train transforms excess power from the grid into potential energy stored as compressed air underground.

Heat exchangers capture heat generated by compressing air and return it during the electrical generation process. Compressed air powers the air turbine generator, which then delivers dispatchable electricity at 13.8 kV. And last but not least, the transformers ensure grid compatibility by converting the 13.8 kV electricity into 230 kV.

This entire process can’t happen without the thermal storage tanks built more than 2,000 feet above the storage cavern, shafts, and reservoir. Together, six hot-water thermal storage tanks and two cold-water storage tanks capture and reuse heat from the compressed air process to generate and dispatch electricity back to the grid. These critical structures above ground work with their counterparts deep underground to store, move, and dispatch excess energy between Willow Rock and the grid in a closed-loop system.

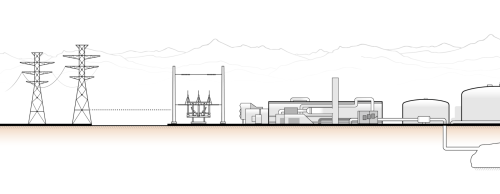

4. Transmission line interconnection

The fourth phase of the project connects Willow Rock to the grid by building a transmission line, which is required to store and deploy through the grid. Like all Hydrostor sites, Willow Rock is located close to a grid interconnection point. This strategic location reduces the time, cost, and complexity of connecting to the transmission line.

Over 15 months, a team of 30 workers will install a 19-mile-long, 230 kV transmission line supported by 125 transmission poles. When this phase is done, the Willow Rock Energy Storage Center will be connected to the nearby Whirlwind Substation and is almost ready to come online.

5. Testing and adjustments

Once construction is complete, the essential fifth stage of bringing the Willow Rock Energy Storage Center online begins. Over 15 months, 100 workers rigorously test and fine-tune each and every installation and structure above and below ground to ensure they perform reliably, safely, and efficiently.

Just as preconstruction planning ensures community, worker, and environmental safety, post-construction testing and adjustments guarantee Willow Rock can run optimally and deliver on its mission for 50-plus years.

6. Startup and operations

Now the finish line approaches. Over the course of five final months, up to 100 workers will start up Willow Rock’s A-CAES technology to bring it online. This involves filling the water reservoir to fully charge the system and prepare Willow Rock to store and dispatch energy.

Once online, Willow Rock will provide Kern County with an emissions-free, long-duration energy storage system ready to deliver a full workday’s worth of power whenever California needs it—and built to last for generations to come.

Hydrostor Inc.